Whether you rip a stack of boards or make precision grooves for cabinetry, this list makes the cut for some of the best table saw blades.

BobVila.com and its partners may earn a commission if you purchase a product through one of our links.

Photo: depositphotos.com

While a good table saw makes large jobs easier and more accurate when it comes to cutting wood, it’s only as good as its blade. A quality blade used for the right job can help you achieve the intended results, but the wrong blade can quickly ruin a DIY project.

Stroll through the saw blade section of the tools department in your local home improvement store, and you’ll soon realize that you have many options to consider. Selecting the right blade for your table saw and projects can be confusing.

Whether you need a quality all-purpose blade to cover all your needs or a specialty blade for making ripping lumber more efficient, read on to learn about some of the best table saw blade options available.

- BEST OVERALL: Forrest WW10Q407125 Woodworker II

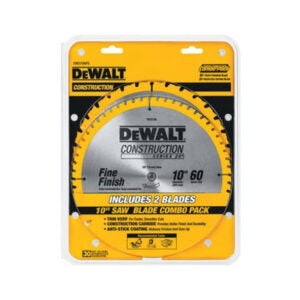

- BEST BANG FOR THE BUCK: DEWALT 10-Inch Miter / Table Saw Blades

- BEST FLAT-TOOTH RIPPING: Freud 10” x 24T Heavy-Duty Rip Blade (LM72R010)

- BEST COMBINATION: Freud D1050X Diablo 10″ 50-tooth Combo Saw Blade

- BEST DADO: Oshlun SDS-0630 6-Inch 30 Tooth Stack Dado Set

- BEST FOR PLYWOOD: Freud 10″ x 80T Ultimate Plywood Blade (LU80R010)

- BEST FOR HARDWOOD: Concord Blades WCB1000T030HP 10-Inch 30 Teeth

Photo: depositphotos.com

Types of Table Saw Blades

Understanding how saw blades meet specialized needs is crucial to picking the right one for the job. Below are some common types of saw blades you can buy.

Crosscut

Manufacturers design crosscut saw blades to make smooth cuts across the wood’s grain. These saws have more teeth and feature fewer gullets. A 10-inch crosscut blade may have 60 to 80 teeth, allowing it to make more cuts with each revolution than a ripping or a combination blade.

With fewer spaces between the teeth, crosscut blades remove less material, resulting in a smoother cut. It also means it takes these blades longer to move through wood. Crosscut blades are an excellent choice for finish carpentry and other applications that require precision and a smooth finish.

Flat-Tooth Ripping

Ripping blades are designed to cut along or with the grain of the wood. Since it’s easier to cut with the grain than against it, these blades feature flat teeth configurations that can quickly remove large chunks of wood. Ripping blades typically have 10 to 30 teeth with more severe teeth angles of at least 20 degrees. Fewer teeth on the blade allow for more gullets for removing material.

While this design makes ripping blades ideal for rip cuts, they are not ideal for cross cuts since they produce too much tear-out, (the amount of wood removed with each cut,) plus this type of blade often leaves behind ragged edges.

Combination

General-purpose combination blades can handle both crosscuts and rip cuts. Combination blades find a middle ground between crosscut and ripping blades with 40 to 50 teeth. While they may not be the best blade for ripping or cross cuts, they can do both effectively, eliminating the need to change blades mid-project. Combination blades work well for projects that demand both types of cuts but don’t necessarily need the smooth finish of a crosscut blade or the speed of a ripping blade.

Dado

A dado blade is a specialty blade used to create wide grooves in wood for shelving, door panels, and drawers. Whereas other saw blades consist of one flat metal blade, dado blades come in two different designs: stacked and wobble.

Stacked blades consist of multiple cutters and spacers sandwiched together to create a wider profile. Manufacturers configure stacked blades with ripper style blades and spacers in the middle and crosscut blades outside. This setup allows the blade to remove large amounts of material while maintaining a smooth cutline along the groove’s edges.

Wobble blades rotate in an offset pattern to cut wide grooves as they spin through the wood. Wobble blades include an adjuster that alters the width of the wobble. Although wobble blades don’t offer the same quality cut as a stacked blade, they are usually lower-priced.

What to Consider When Choosing the Best Table Saw Blade

Determining which table saw blade is right for your needs can be overwhelming. Read on to learn about the factors to consider before making a purchase.

Job Type

Most DIYers can get away with a single combination blade for all of their project needs. Combination blades make both rip cuts and crosscuts across standard lumber while leaving edges clean enough to meet most project demands. Combination blades also reduce the added cost of buying multiple blades and also save time by eliminating the need to switch the blades between cuts.

Ripping, crosscut, and dado blades offer more specialized cutting and are must-haves for many carpentry projects such as furniture, cabinetry, and built-ins. For jobs that involve a lot of ripping, purchase a ripping blade, which will save time and effort while still leaving a clean edge for joining pieces of wood. A rip cut blade is also ideal for cutting hardwoods as it will cut through this tougher material without wearing out the blade.

Keep a cross-cut blade handy for ultra-smooth carpentry cuts. Crosscut blades offer the cleanest cutting edge, making them ideal for woodworking projects that require precision cuts. A dado blade is a must-have for shelving, furniture, and cabinetry projects that require recessed grooves.

Blade Kerf

Kerf refers to the thickness of the blade. The higher the kerf, the more material is removed with each cut. A full kerf blade is 1/8-inch thick. Thicker kerf blades resist bending while moving through the wood; however, they require more power from the saw to work effectively. Most table saws can handle standard 1/8-inch blades. If your table saw is equipped with less than 3 horsepower, consider using a thinner kerf blade. Thin kerf blades require less power, are more precise, and create less waste with each cut but are more likely to warp while cutting through the wood.

Blade Length

Blade size does affect performance. Smaller blades on equally powered saws spin faster, resulting in smoother cuts. A 12-inch blade requires more power to rotate and is more likely to wobble than a smaller blade. As such, a larger blade won’t make as precise a cut as a smaller one but does offer greater depth, allowing it to cut through thicker boards.

Most tables saws use 10-inch blades, although there are some variances, so check your table saw before making a purchase. While it is possible to fit a table saw with a smaller blade, never attempt to equip a 10-inch table saw with a larger blade.

Blade Teeth Configuration

The configuration of a saw blade’s teeth affects how the blade cuts the wood. Flat top blades are more effective at cutting through wood. These blades rip out material in large chunks, therefore, increasing the cutting speed. Since they also leave ragged edges, these blades are a good option for rip cuts.

- Crosscut blades feature bevels that alternate in direction, resulting in smoother cuts for finish carpentry.

- Combination blades use a hybrid approach, which mixes flat top teeth with alternate bevel teeth. That allows the blade to make crosscuts and rip cuts but still maintain a relatively smooth edge.

In addition to these standard configurations, there are also specialized blades for cutting various other materials, including metal, masonry, and wood laminates.

Tooth Gullet

The gullet is the space between each blade. It determines how effectively the blade removes material with each cut. Blades designed to remove material quickly, such as rip blades, have deeper gullets. Precision-cut blades, such as crosscut blades, feature smaller gullets, and are designed to make smoother cuts.

Additional Features

Many manufacturers equip their blades with additional features that improve durability and performance. Look for blades that offer anti-vibration slots, which prevent warping during use.

High-quality blades will also offer higher-quality materials such as carbide-tipped blades. These hardened tips hold up better than other materials, which extends the life of the blades. Consider blades with lubricating coatings that improve blade life and allow for faster cutting.

Tips for You to Buy and Use a Table Saw Blade

When you determine what saw blade to purchase, there are a few additional considerations you should make to ensure your blade works properly with your table saw.

- Identify how powerful your table saw is before you purchase a blade. A table saw with three or more horsepower is better equipped to handle thicker blades while a lighter-duty saw might be better suited for thinner blades.

- Keep an eye out for hand-tensioned blades. These are blades that have been precision flattened by hand. Hand-tensioned blades offer the least amount of wobble and hence the highest grade of accuracy.

- Pay attention to the material. High-grade materials such as C-4 carbide offer greater durability. While these may cost more, they’ll require less maintenance and will last longer.

- When you cut wood, be patient. If you attempt to push the material too aggressively through a blade, it is dangerous and will also diminish the quality and accuracy. Be patient and feed wood into the blade at a pace it can handle.

Our Top Picks

From some of the best all-purpose saw blades that can handle various cutting demands to some of the best specialty blades to cut grooves and rip boards, read on to review some of the highest-rated table saw blades.

Best Overall

While the price for this top-of-the-line table saw blade might seem excessive, it’s high performance and multi-use capability makes it worth the extra cost. With its alternate bevel teeth configuration, this blade performs both rip cuts and crosscuts with ease—no more changing blades. It also ends rough edges and the need for second-step finishing. The quality is also top-notch. With hand-tensioning and C-4 carbide construction, expect maximum precision. You won’t endure wobbling with this blade. And while the Woodworker II comes with a much higher price tag, it is made from harder metal than other blades. That means that it will last several times longer than lower-priced blades, helping to cut out extra costs. These blades come in a wide array of sizes.

Best Bang for the Buck

Priced at just a fraction of other blades, DeWalt offers the best deal you can find when it comes to outfitting your table saw. Are you looking to rip boards or make precision crosscuts? DeWalt has two-blade sets, so both jobs are covered. You can use the combination blade for everyday cuts and the crosscutting blade for precision cuts. A thinner kerf allows you to cut faster and smoother, which makes this blade set an excellent option for hardwoods, softwoods, and plywood. It’s also best used for miter saw and slide miter saw jobs. Tungsten carbide construction adds durability, ensuring a lot of life out of this blade set. The tougher tungsten carbide also stays sharper for a longer time than many of its competitors. Features include a computer-balanced plate that reduces vibration for improved accuracy and a better finish.

Best Flat-Tooth Ripping

Let it rip with this heavy-duty saw blade from Freud. With its flat-tooth design and deep gullets, this 10-inch blade makes short work of your wood ripping jobs. Four anti-vibration slots reduce wobbling and allow for smoother cuts. The blade’s 24 teeth are made of high-density carbide that Freud refers to as its “ripping blend,” meaning it will last longer and hold up better whether cutting softwoods or hardwoods. The extra-large, flat tooth design leaves a smooth finish and eliminates the need to sand or joint. With its Silver I.C.E coating that resists build-up from the sticky pitch in lumber, this blade also requires less maintenance then similarly-priced rip blades. The Perma-Shield Non-Stick Coating reduces drag, protects the blade from corrosion as well as from pitch build-up.

Best Combination

With its unique blade design and set of 50 teeth, this saw blade sits right in the sweet spot between ripper and crosscut to make an excellent combo blade. The Diablo breaks up its 50 teeth into ten sets of five. Each group includes closely-set teeth angled just aggressively enough for ripping while still maintaining a smooth finish for crosscutting. The large gullets that separate each group can remove large amounts of material when making rip cuts. The laser-cut stabilizer vents trap noise and vibration, which keeps it cool and reduces blade warp. Laser-cut heat expansion slots allow the blade to expand due to heat build-up, which holds the cut true and straight. Add to that, its durable shock-resistant carbide construction, and you have a blade that’s ready to take on the lion’s share of your table saw’s workload.

Best Dado

With plenty of pieces to create a near-endless variety of configurations, this deluxe dado set from Oshlun offers everything a woodworker needs to cut precision grooves for cabinetry, shelving, and a whole host of other fine carpentry applications. Oshlun made the 16-piece stack set from professional-grade C-4 carbide. It includes a mix of chippers for removing large chunks of wood, and high tooth-count saw blades for creating smooth edges and shims for fine-tuning groove width. Tungsten carbide tips stand ready to take on plywood as well as both softwoods and hardwoods. These are smaller 6-inch blades that require less power to reach high RPMs but may not be compatible with all table saws. The blades come with a storage/carrying case.

Best for Plywood

The outer veneer layer of plywood is notorious for chipping when pushed through a table saw. Sometimes, this can result in having to make messy wood filler repairs. Cutting sheets of plywood tends to come easy with Freud’s ultimate plywood and melamine blade. Its 80 teeth, shallow gullets, a razor-thin .098-inch kerf, and a conservative 2-degree hook angle helps this blade to produce smooth chip-free cuts through plywood. The additional features—including anti-vibration slots to reduce wobble and a non-stick finish coating that reduces blade drag—help to make your work easier. It also works well for rip cuts without having to switch out blades. Beware, though, the wood will burn if you let the blade set too long.

Best for Hardwood

Concord’s general-purpose blade works well on softwoods but is even tougher on hardwoods thanks to its 80-tooth shallow angle blade design and a thin kerf. This professional-quality, construction-grade blade excels at ripping and crosscutting thick hardwoods up to 3 1/2 inches thick and softwoods up to 1-inch thick. It also works well on exotic woods and abrasive woods.

The thin kerf lets you achieve a smooth finish with minimal waste. A lower hook angle improves the surface quality of the cut. This blade manages hardwood crosscuts while at the same time executing precision rips cuts. Although it’s slow going through hardwood, it rewards patience by routinely offering smooth edges. Just don’t expect a long life out of this blade. Hardwoods tend to wear out saw blades quickly, and this one is no exception. But, given how affordable it is, it’s a high-performing option that you won’t mind replacing.

FAQs About Your New Table Saw Blade

Changing blades, making the right cut, adjusting your kerf; read on to find the answers to your most pressing concerns regarding table saw blades.

Q. Why do I get wider cuts than the blade kerf?

If you get wider cuts than the blade’s kerf, it’s likely because the blade is wobbling under the pressure of cutting. Eliminate the wobble by purchasing blades that feature cut-outs to help reduce tension.

Q. How do I change a table saw blade?

Changing a table saw blade is done by applying a socket wrench to the large nut holding the blade to the table saw. Most table saws include a locking button or mechanism that immobilizes the blade so you can loosen this bolt. If not, use a second wrench to hold the bolt’s head in place while you loosen the nut.

Q. How do I use a dado blade on a table saw?

Begin by stacking the blades and shims to the thickness of the groove you’re trying to create. Make sure to keep the shims and chipper blades on the stack’s interior and the saw blades on the exterior. Install the blades as you would a normal saw blade and adjust the height to achieve the exact depth of cut you need.

tinyurlis.gdv.gdv.htclck.ruulvis.netshrtco.de

مقالات مشابه

- سرباز مجرم در وست پوینت رول اور که به کشته شدن دانشجوی دانشکده افسری

- آیا زمان حرف زدن بیشتر درباره داروهای گیاهی است؟

- شرکت صادرات و واردات کالاهای مختلف از جمله کاشی و سرامیک و ارائه دهنده خدمات ترانزیت و بارگیری دریایی و ریلی و ترخیص کالا برای کشورهای مختلف از جمله روسیه و کشورهای حوزه cis و سایر نقاط جهان - بازرگانی علی قانعی

- شرکت صادرات و واردات کالاهای مختلف از جمله کاشی و سرامیک و ارائه دهنده خدمات ترانزیت و بارگیری دریایی و ریلی و ترخیص کالا برای کشورهای مختلف از جمله روسیه و کشورهای حوزه cis و سایر نقاط جهان - بازرگانی علی قانعی

- اردن 27 مظنون به قاچاق مواد مخدر را در تیراندازی مرزی کشت

- 6 مواد شیمیایی اشتباهاتی که در چهار سال

- قیمت میلگرد سیاه در بازار تهران

- شرکت صادرات و واردات کالاهای مختلف از جمله کاشی و سرامیک و ارائه دهنده خدمات ترانزیت و بارگیری دریایی و ریلی و ترخیص کالا برای کشورهای مختلف از جمله روسیه و کشورهای حوزه cis و سایر نقاط جهان - بازرگانی علی قانعی

- سربازان گارد ملی فعال برای مغلوب ساختن پیشی جستن تجمع در تولسا

- شرکت صادرات و واردات کالاهای مختلف از جمله کاشی و سرامیک و ارائه دهنده خدمات ترانزیت و بارگیری دریایی و ریلی و ترخیص کالا برای کشورهای مختلف از جمله روسیه و کشورهای حوزه cis و سایر نقاط جهان - بازرگانی علی قانعی